Product Description

Product Details

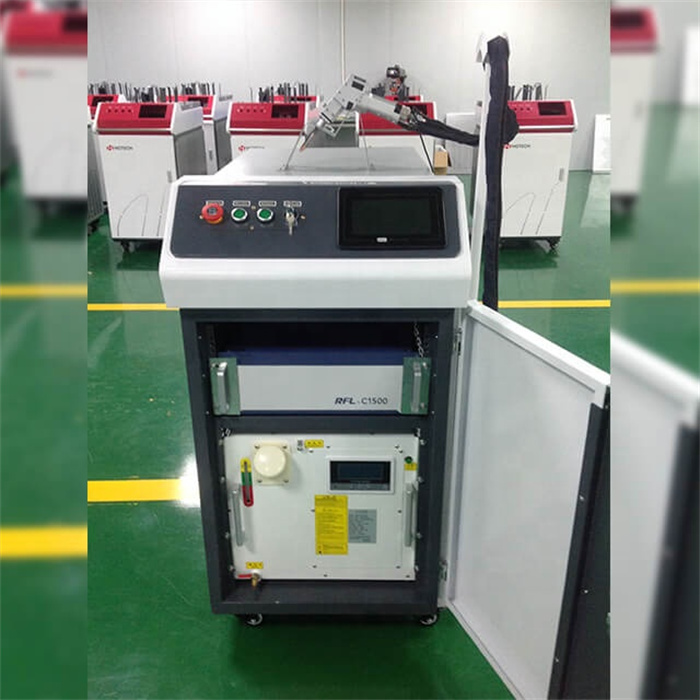

Welding head

Control panel

Laser source

Chiller

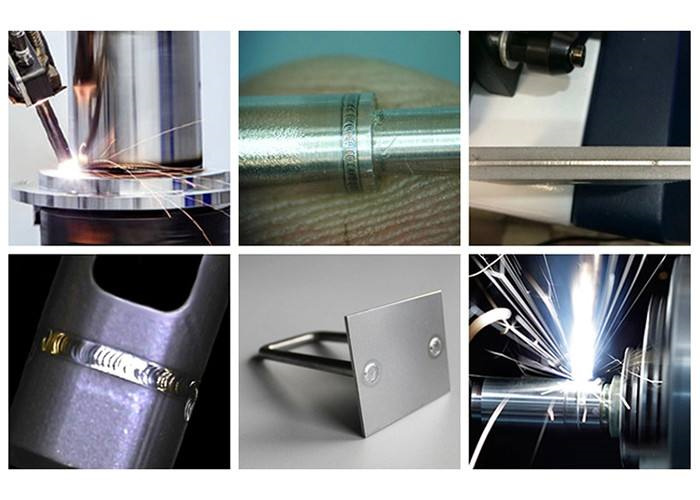

Product Application

Laser Welding Machine is widely used in mobile phone battery shell, electronic components, mobile communication, precision equipment, hardware products, automotive accessories, glasses, clocks, jewelry, medical equipment, thermal cups, wine pots, kitchens and other industries.

TECHNICIAL PARAMETERS | |||

Model | HY-WF01 | ||

Maximum Laser Power | 500W/1000W/1500W/2000W | ||

The Laser Wavelength | 1.06um | ||

Operation Model | Continuity | ||

Laser Welding Depth | 1mm~4.0mm | ||

Wobble Welding Head | Spot Size (1.0-3.0mm option) | ||

Power Regulation | 10-100% | ||

Wire Feeding System | Option | ||

Positioning System (GPS) | Red light indication | ||

Power Demand | 220V/50HZ/60HZ, 380V/50HZ/60HZ | ||

Cooling Mode | Water Cooling | ||

The Whole Machine Consumes Power | <3KW | ||

The Whole Machine Size | WLH (1200*700*1200mm) | ||

Main Advantages

The Laser welding is to irradiate a high energy density laser beam on two parts of the material, melt the material and then cooling and solidification into one. Compared with traditional welding technology, the Auto wire feeding hand held laser welding has the following advantages:

1. The weld seam is smoothe and beautiful, it doesnot need to be polished or the workboard of the polish is very small.

2. Through control the laser energy, the welding will not defrom or very few deformation.

3. Handheld laser welding machine is easy to handle and needn't to require the professional welders.

4. The wobble welding machine can handle the hard welding material easily, such as aluminum, brass.

5. Long life span up to 100,000 hours and low comsumption.

6. the Auto wire feeding handheld welding machine can weld parts with wider gap.

7. With a 8-15m fiber line, It can weld long-distance and large- area parts.

8. Various welding processes, such as spot welding, seam welding and overlap welding.

9. The welding efficiency is around 5 times of TIG welding.

10. It is welding used in electronics, sheet metal, air condiction industry etc.

Sample

Packing