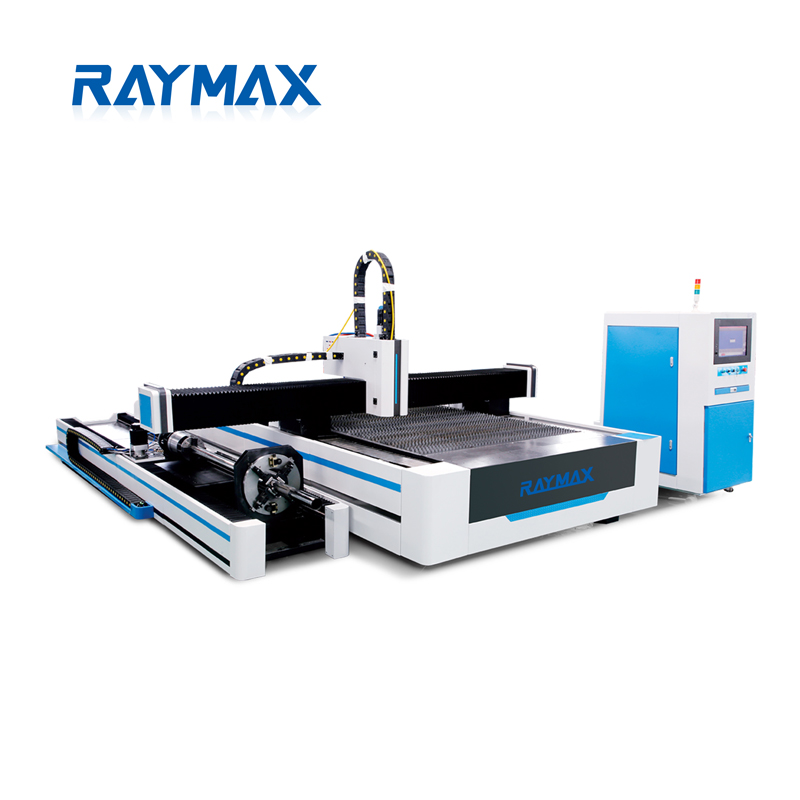

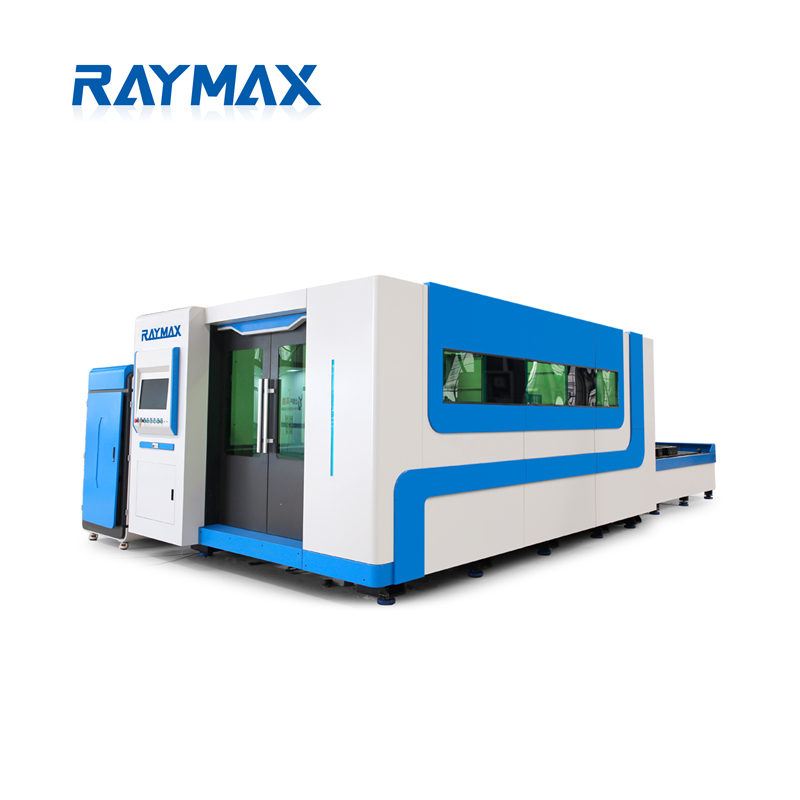

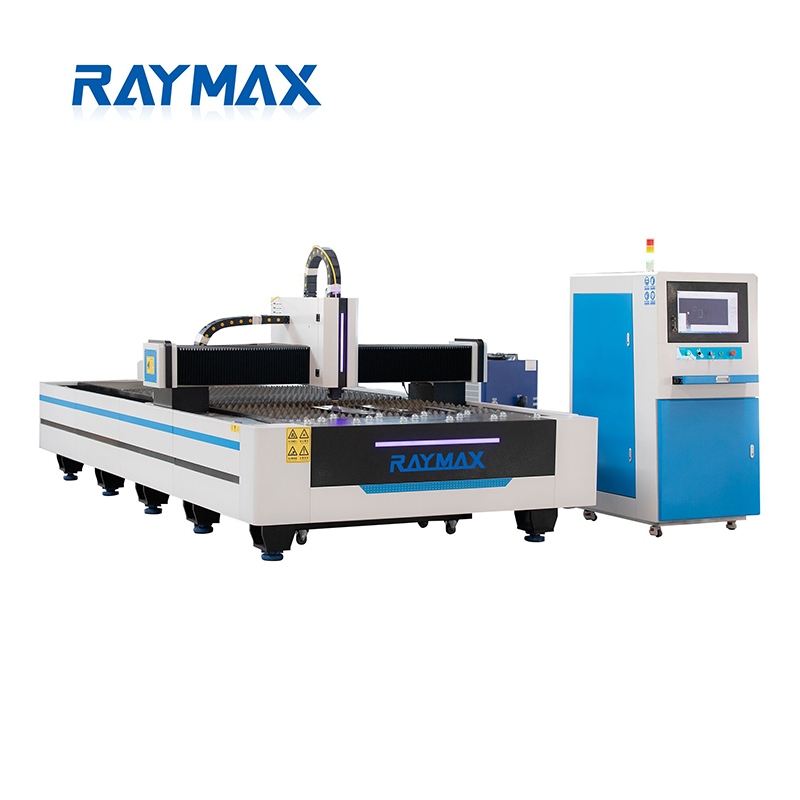

Fiber Laser Cutting Machine

The fiber laser metal cutting machine is also called a fiber laser cutter, which is a kind of CNC laser metal cutting equipment with high quality, high speed, high precision, and high efficiency.

The fiber laser cutter for sale is a mechanical CNC laser cutter that uses a fiber laser source to output a high-energy-density laser beam, which instantly melts and vaporizes the area illuminated by the ultra-fine focus spot on the workpiece, and moves the spot irradiation position through a numerical control mechanical system, thereby achieving cutting.

As China top 10 laser cutting machine supplier, the Zhongrui fiber laser cutter is designed for metal fabrication. Our fiber laser metal cutting machines are equipped with different laser powers (1000W, 1500W, 2000W, 3000W ) for cutting metal sheets and plates, including stainless steel, carbon steel, electrical steel, galvanized steel, aluminum zinc plate, aluminum, aluminum alloy, titanium alloy, copper, brass, iron and other metal materials with different thickness.

How Does A Fiber Laser Metal Cutting Machine Work?

Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. laser cutting can be divided into two types: laser fusion cutting and ablative laser cutting. Laser fusion cutting involves melting material in a column and using a high-pressure stream of gas to shear the molten material away, leaving an open cut kerf. In contrast, ablative laser cutting removes material layer by layer using a pulsed laser—it’s like chiseling, only with light and on a microscopic scale. This generally means evaporating the material, rather than melting it.

The laser emitted by the fiber laser generator is focused by the optical path system into a fiber laser beam of high power density. The fiber laser beam is irradiated onto the surface of the workpiece to bring the workpiece to a melting point or boiling point, while the high-pressure gas coaxial with the fiber laser beam blows away the molten or vaporized material, leaving an edge with a high-quality surface finish. As the fiber laser beam moves relative to the workpiece, the material is slit finally, thereby achieving the purpose of cutting.

Main Features of Fiber Laser Metal Cutting Machine

1. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

2. Extremely high cutting speed: Twice as much as the C02 laser cutting machine with the same power, and at the same time meeting the cutting requirements of plate and pipe.

3. Extremely high stability: Adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours.

4. Low Cost: Save energy and protect the environment. The photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

5. Extremely low maintenance costs: Fiber optic transmission, no need for reflective lenses, saving a lot of maintenance costs.

6. Easy Operations: The product is easy to operate and maintain, with optical fiber transmission, no need to adjust the circuit.

7. Automatic feeding design: Saving loading and unloading time, the steel metal cutting machine can automatically load and unload during the cutting operation, providing more than 30% of the whole work efficiency.

8. Unrestricted by the processing graphics: Professional CNC system, non-contact flexible processing, not affected by the appearance of the processing and the surface of the plate, the high power cutting laser machine can process arbitrary graphics.

Laser Cutting Machine Frame

It’s the mechanical part to realize the movement in X, Y, Z-axis, including cutting working platform. It uses to move the cut workpiece and can move accurately and accurately according to the control program. It usually drives a servo motor. High precision and high stability machine tools help to improve the precision of laser cutting.

Tube Welded Bed

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by a number of rectangular tubes. Moreover, the rectangular tube has a wall thickness of 10 mm and the entire body weighs 4,500 kg, it makes the machine run stably. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the bed, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the bed.

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons of press extrusion molding. After aging treatment, its strength can reach T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, lightweight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Fiber Laser Source

A device that produces a laser light source. The laser source is the heart of the whole machine and the most “power source of laser equipment. It is the most expensive part of fiber laser metal cutting machines.

Laser Cutting Head

The cutting head is a laser output device of a fiber laser cutting machine, which is composed of a nozzle, a focusing lens, and a focus tracking system. The cutting head drive device is used to drive the cutting head moves along the z-axis in accordance with the program. It has the advantages of optimized optical configuration and smooth and efficient airflow design; fully upgraded dust-proof design, double-layer protection, the risk of contamination of the lens is almost zero.

CNC System

The CNC control system mainly controls the machine tool to realize the movement of the X, Y, and Z axes, and also controls the output power of the laser. Its quality determines the stability of the operating performance of the fiber laser cutting machine. The control system is the leading operating system of the fiber laser metal cutting machine.

Double Temperature Double Control System

Fiber lasers above 500W need to be equipped with a fiber laser chiller. The higher the power, the higher the cooling capacity of the fiber laser chiller. Because the laser body and the lens need to be cooled inside the fiber laser, a dual-temperature dual-control chiller can be used to simultaneously cool the laser body and lens.

The Applications of Fiber Laser Metal Cutting Machine

1. Applicable materials

The fiber laser metal cutting machine can cut all kinds of metal materials such as stainless steel, carbon steel, various alloy steels, copper, aluminum, titanium, aluminum alloys, titanium alloys, pickling plates, galvanized plates, and galvanized aluminum.

2. Applicable industries

The fiber laser cutter for sale is widely applied in chassis cabinets, agricultural machinery, advertising production, kitchen and bathroom, sheet metal processing, environmental protection equipment, auto parts, machinery manufacturing, metal handicrafts, hardware products, elevator equipment, and other industries.