Primary maintenance of hydraulic power press machine

1. The working oil is recommended to use No. 32 and No. 46 anti-wear hydraulic oils, and the oil temperature is within the range of 15-60 degrees Celsius.

2. The oil is allowed to be added to the oil tank after strict filtration.

3. The working fluid should be replaced once a year, and the first replacement time should not exceed three months.

4. The sliding block should be lubricated frequently, and the exposed surface of the column should be kept clean frequently, and lubricating oil should be sprayed before each work.

5. The maximum allowable eccentricity of the concentrated load is 40mm under the nominal pressure of 500T. Excessive eccentricity may cause strain on the column or other undesirable phenomena.

6. Calibrate and check the pressure gauge every six months.

7. If the industrial hydraulic press machine is out of service for a long time, the surface of each part should be scrubbed clean and coated with anti-rust oil.

Secondary maintenance of hydraulic power press machine

1. The hydraulic power press machine tool runs for 5000 hours for secondary maintenance. Mainly maintenance workers, operators participating. In addition to the implementation of the first level of maintenance, the following work should be done, and the wearing parts should be surveyed and mapped, and propose spare parts.

2. First cut off the power supply for maintenance work. (See table below)

| Number | Maintenance part | Maintenance content and requirements |

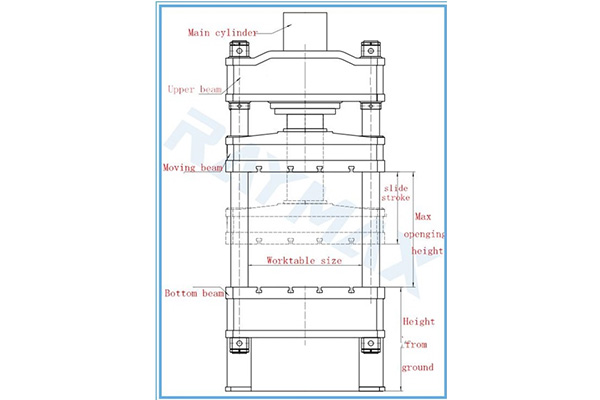

| 1 | Beam and column guide | 1. Check and adjust the horizontal beam plane, column guide rail, guide sleeve, slider, and pressure plate to make it move smoothly and meet the process requirements. 2. Repair or replace missing parts. |

| 2 | Hydraulic lubrication | 1. Disassemble, wash, and repair solenoid valves, grinding valves, and valve cores. 2. Clean and check the oil pump cylinder plunger to repair burrs and replace the oil seal 3. Check the pressure gauge 4. Repair or replace severely worn parts 5. Drive to check that the cylinders and plungers are running smoothly and there is no creeping. The support valve can make the movable beam stop accurately at any position, and the pressure drop can meet the process requirements. |

| 3 | Electrical appliances | 1. Clean the motor, check the bearing, update the grease 2. Repair or replace damaged components. 3. The electrical appliances meet the requirements of the equipment integrity standard. |

| 4 | Precision | 1. Calibrate the level of the machine tool, check the adjustment and repair accuracy. 2. Accuracy meets the requirements of equipment integrity standards. |

The maintenance of the hydraulic power press machine still requires dedicated, professional, and full-time maintenance, so that it can take longer!