The DA-58T is a state of the art complete 2D graphical control solution for synchronized press brakes. Its 15" high resolution colour TFT, with industrial grade multi touch screen technology, gives access to the proven Delem user-interface. It enables direct navigation between product programming and actual production. Functions are directly located where needed, offering optimized ergonomics throughout the entire application.

The Main feature

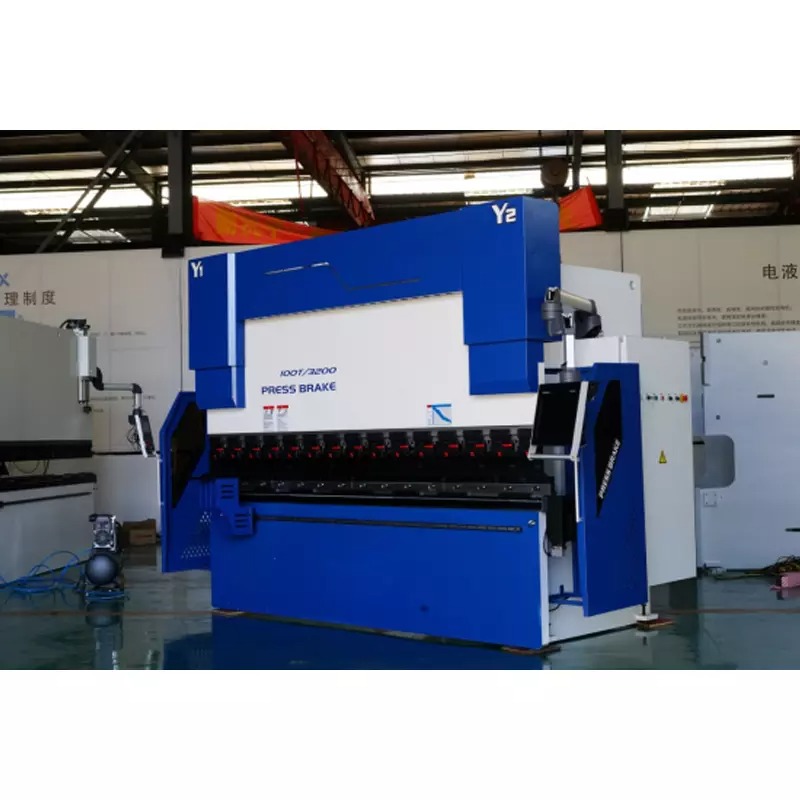

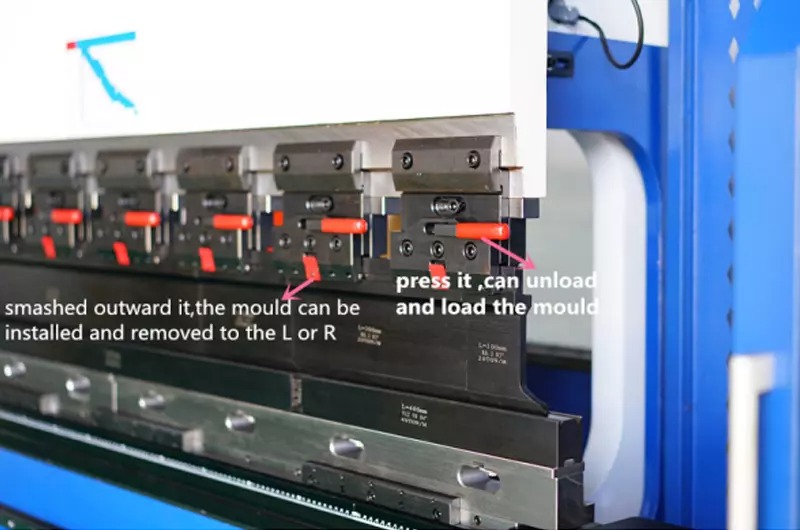

• It is designed especially for bending in decoration industry, which solving the large deformation of stainless steel sheet. Entire steel welded frame and slide with annealing treatment to eliminate internal stress, which can against deformation and with good accuracy .frame is steel structure, left and right vertical plate, table and pressure plate welded into a unitary structure, after welding to eliminate internal stress by tempering, exceptional rigidity, high stability.

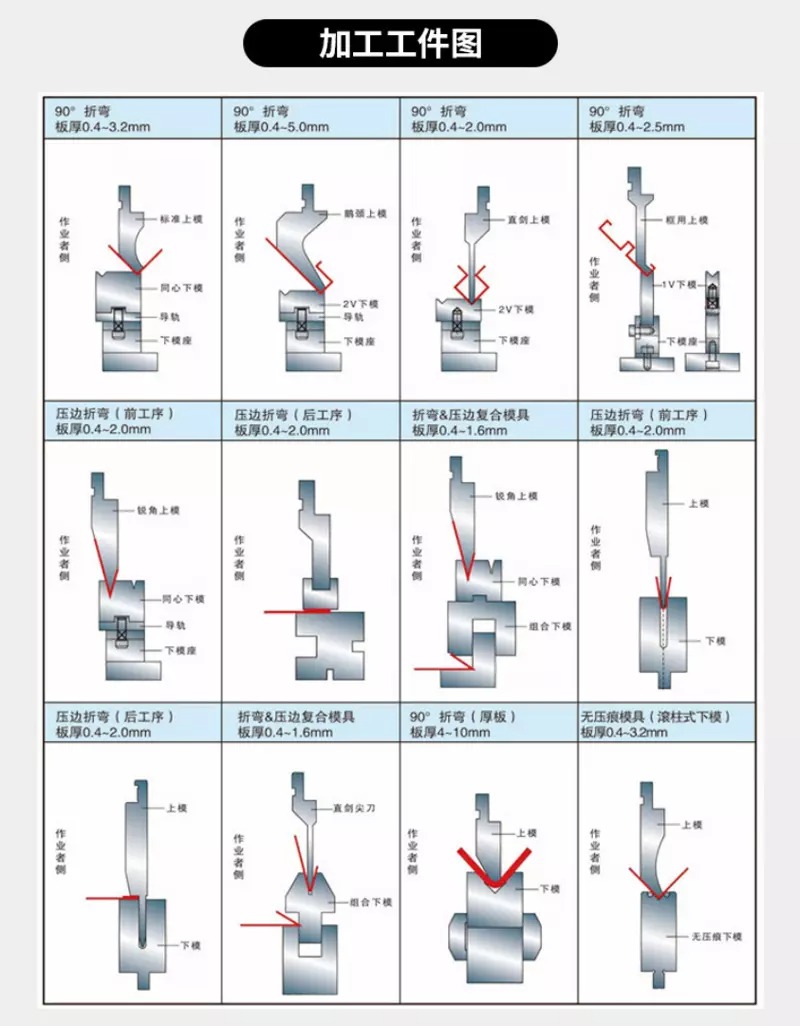

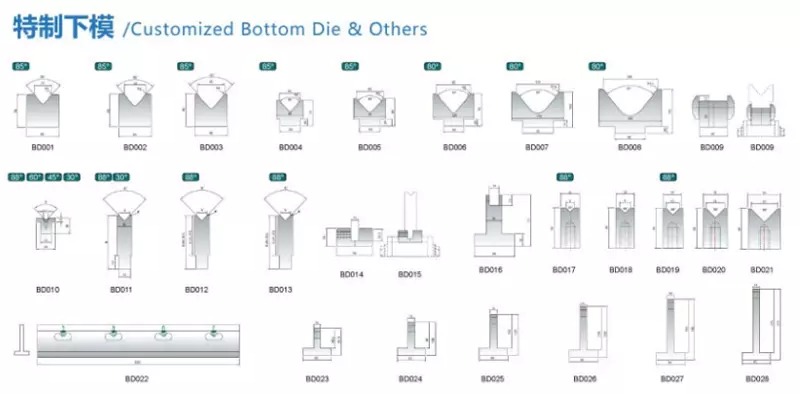

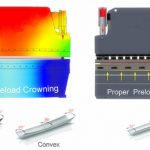

• Wedge compensation structure of upper die and lower bolster with high accuracy and optimized die slot angle, square slot of lower part to reduce elastic deformation of stainless steel sheet .

• Hydraulic drive, cylinder on both end of machine, disposed on the slider to drive it work directly.

• Torsion axis synchronization for slide synchronous mechanism.

• The stroke of cylinder ( Y1,Y2) and back gauge (X,Y,Z )are computer controlled The back gauge moved in left and right direction of linear guide to promote positioning accuracy

• Back Gauge size and slide stroke controlled by CNC system, back gauge with high precision ball screw, stable operation and precise positioning.

• The CNC system adopts frequency conversion control technology, with multi-step

programming function, simple and easy to operate.

• Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

• Safety barrier device all around the machinery, electrical cabinets equipped with Open door cut-off function, emergency stop button around front and back, protective cover foot switch to ensure safe working.

The whole machine is in a welded sheet structure, with internal tension eliminated by vibration aging technology, high strength and good rigidity of the machine. The long service life of the machine is ensured.

LED light, it is easier and safer when the environment is dark for the operator

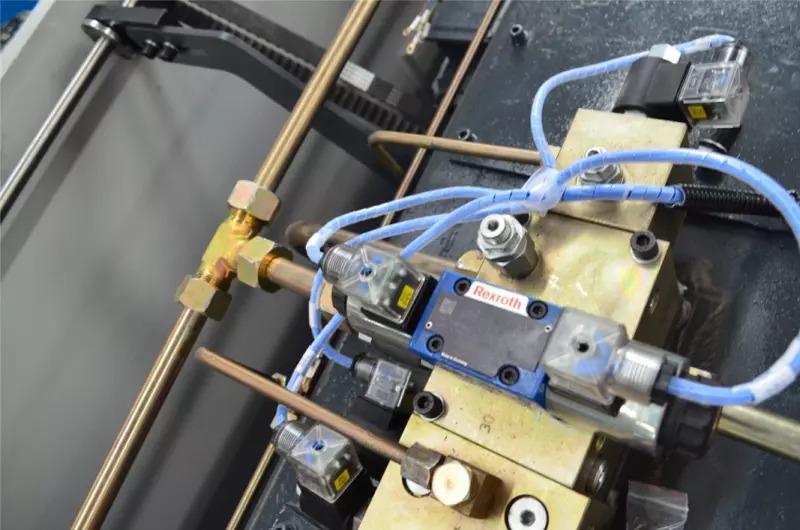

Hydraulic system with overload overflow safety protection

Hydraulic clear and intuitive display of oil level

The machine can work continuously under rated load

hydraulic system decreased the pipe connections, oil leakage, and increased the stability and overall beautifiest

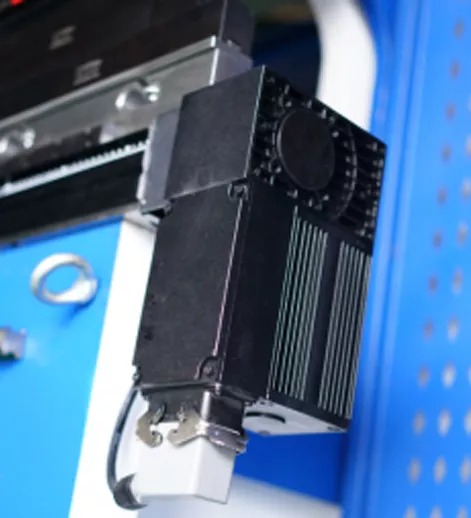

The backgauge ,it is made of high-strength aluminum alloy material, driven by servo motors, and uses ball rods and linear guide rails, with good positioning accuracy

Full envelope design free of maintenance

4+1 axis : Y1+Y2+X+R+Crowing

High precision backgauge device, Taiwan HIWIN ball screw and linear guide rail. Backgauge adopts horizontal shell installation structure with high reliability, and single-shell double linear guide rails with high precision X-Axis drive.

Good adrasion resistance and long service life maintain convenience and can improve the accuracy of the backgauge .

Double structure front arm is higher rigidity ,superior carrying capacity .It can be adjusted up and down or move along the workbench from side to side

For input plate thickness and length parameterizing digital system ,the system will automatically compensate the deflection

Video

Detail

The DA-58T is a state of the art complete 2D graphical control solution for synchronized press brakes.

Its 15" high resolution colour TFT, with industrial grade multi touch screen technology, gives access to the proven Delem user-interface. It enables direct navigation between product programming and actual production. Functions are directly located where needed, offering optimized ergonomics throughout the entire application.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence. CNC programs are generated with a single touch. You are immediately ready to make the first part since all axes positions are automatically computed and the bend sequence has been simulated with machine and tools in real scale.

The DA-58T offers 2D programming including automatic bend sequence calculation and collision detection.

The production mode of the DA-58T helps the operator in graphically simulating the bend process of the product, guiding him during the press brake operation.

The standard machine control functions are Y1-Y2 and X axis. A second back gauge axis can be used as R or Z axis. Also crowning control is standard on board.

DA-58T features:

· 2D graphical touch screen programming

· 15" high resolution colour TFT

· Bend sequence calculation

· Crowning control

· Servo and frequency inverter control

· Advanced Y-axis control algorithms

· USB, peripheral interfacing

· Profile-58TL offline software

Technical