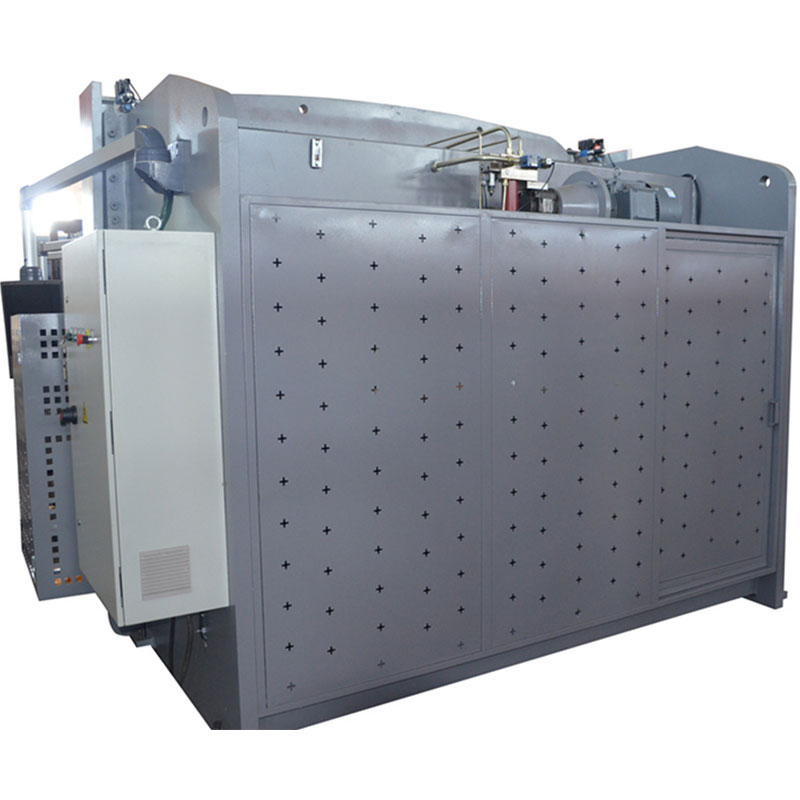

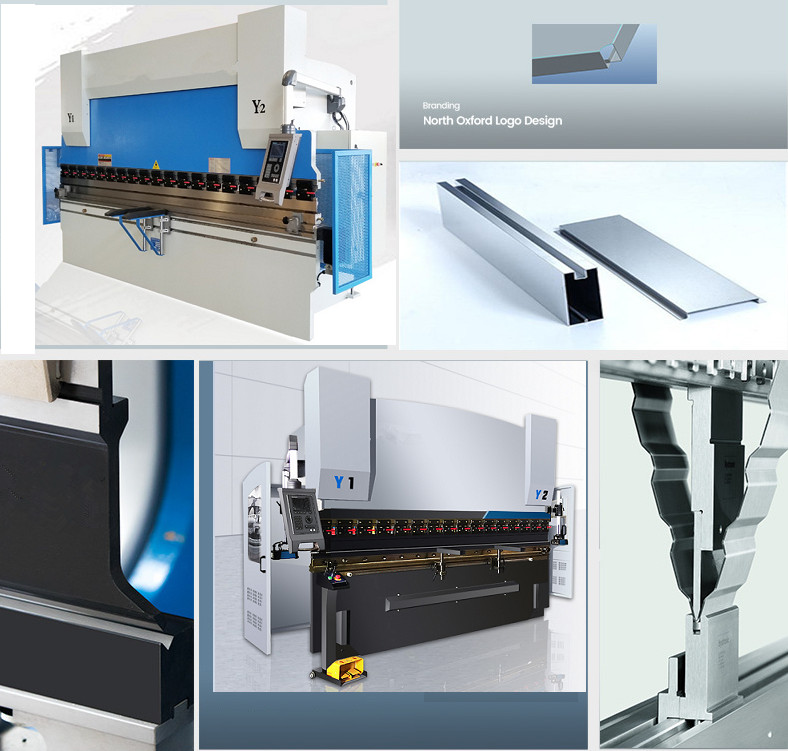

CNC series Electro hydraulic serve pump controller CNC press brake machine is of servo main motor which drives 2 way pump to control dual oil cylinder synchronously mechanical (hydraulic) crowning compensation device is equipped

The sheet metal press brake features energy saving by 50%, oil volume saving by 70% compared with traditional hydraulic press bake machine.

Multi backgauge axes are available steel weld machine frame gets annealing treatment with constant accuracy Netherlandish DELEM DA52&DA58

The Main Feature

● Overall welded and processed structure

● Dual cylinders synchronous controlled by electro-hydraulic servo vale, ensure the highest controlling precision, bending accuracy and repositioning accuracy are also reach the highest level

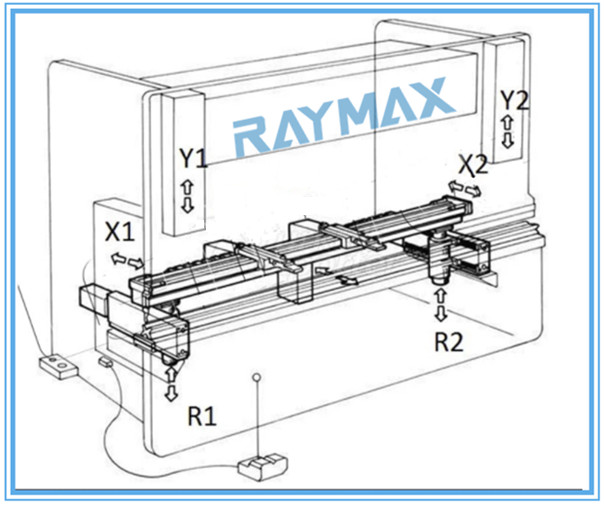

● Backgauge mechanism can control several backgauge axes

● Hydraulic compensation mechanism helps to prevent the deformed slider from affecting the quality of the workpiece, and the compensation mechanism is adjusted automatically by the CNC controller which is convenient and accuracy

● WF67K Series machines redesigned based on users preferences to become a unique press brake bending machine with its individual electronic and mechanical features.

● WF67K Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum level with its user friendly CNC controller and low cost hydraulic maintenance.

● New WF67K is exactly what you need for your production where complicated, sensitive, single or multiple bends on high speed are paramount.

● High quality and repetitive bending is obtained by using synchronized cylinders and valves.

● Automatic utilization of all axes on startup.

● Rigid upper beam runs on 8-point bearings with bending precision of 0,01 mm.

● Well-known top and bottom tool brands are long lasting hardened and provide precise bending.

● The hydraulic press brake machines are designed using SOLID WORKS 3D programming and made with enhanced ST44-1 quality steel using the latest Technology.

DA52S CNC controller

The new generation DA-Touch controls offers an even higher grade of efficiency in programming, operation and control of today's bending press brake machine. Ease of use combined with state-of-the-art technology go hand in hand, improving productivity.

DA52S

● Numerical, one page programming

● 6.4"LCD TFT color display

● Crowning control

● Tool library

● Optional second backgauge axis

● USB, memory stick interfacing

● Advanced Y-axes control algorithms for closed loop as well as open loop valves

● Servo, frequency inverter and AC control for backgauge axes

The CNC back gauge

Energy-saving LED light

If the working environment is not bright, LED lights help the operator to operate the machine more easily and safely.

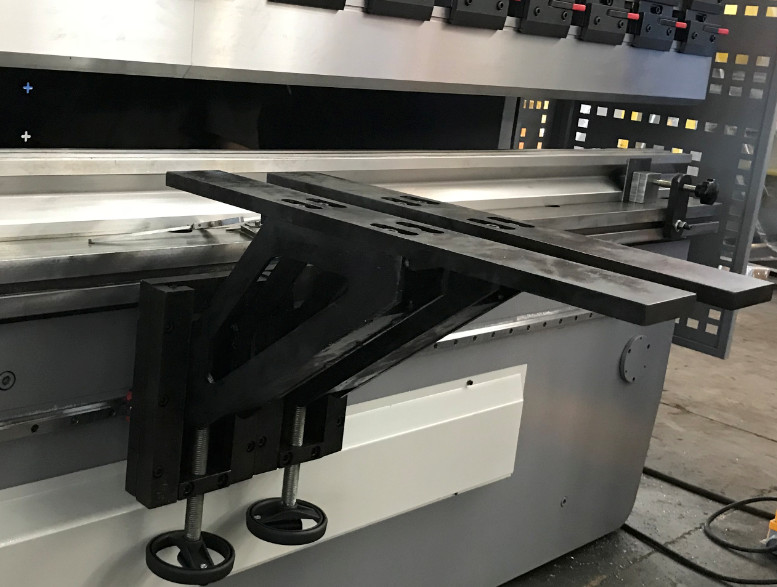

Double structure front arm

Double structure front arm is higher rigidity , longer, superior carrying capacity .

It can be adjusted up and down or move along the workbench from side to side.

Double structure front arm with linear guide

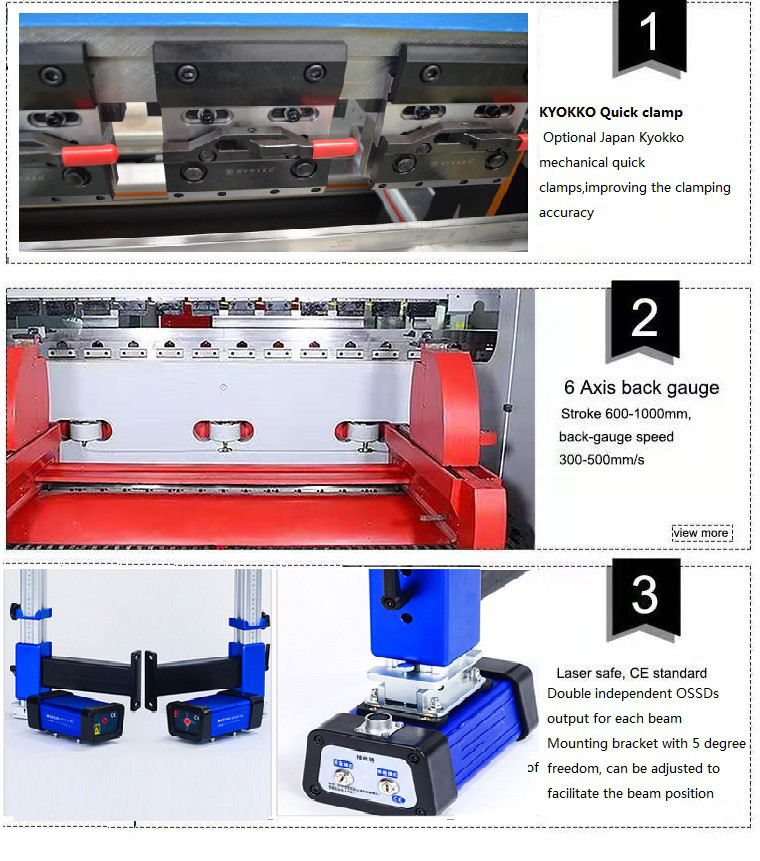

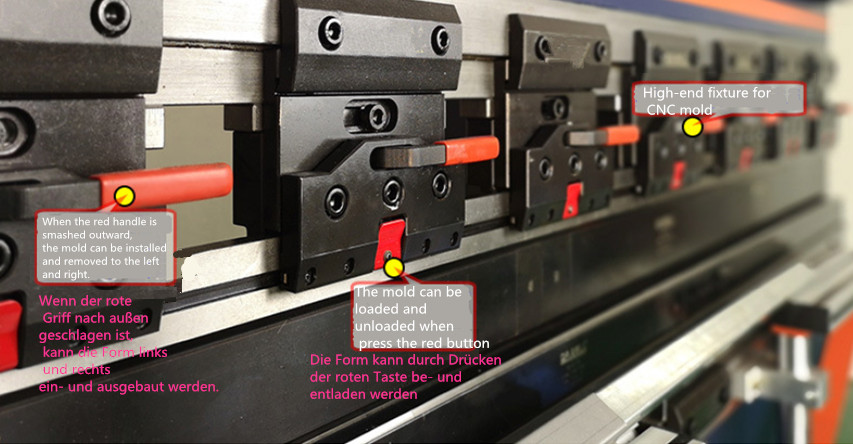

1. The mold can be installed and removed to the left and right when pull the red handle.

2. The mold can be installed up and down when press the button

3. Scale more accurate

4. Save time and easy to change the die

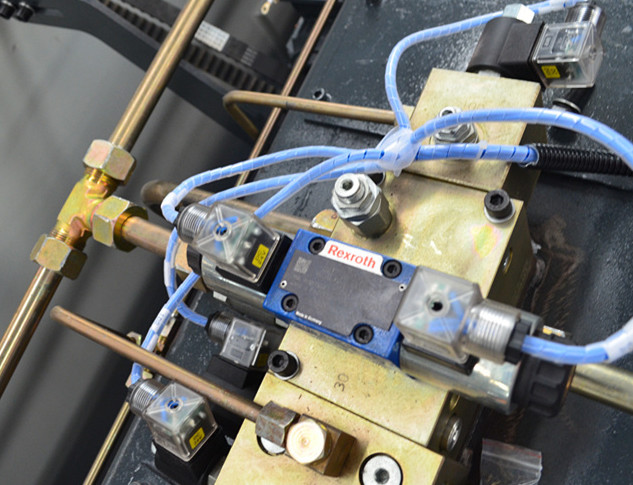

Hydraulic valve -Rexroth

Hydraulic valve -Rexroth from Germany

Hydraulic system with overload overflow safety protection

Hydraulic clear and intuitive display of oil level

The bending press machine can work continuously under rated load and can effectively alleviate problems cause by leakage of hydraulic fluid.

Hydraulic system decreased the pipe connections, oil leakage, and increased the stability and overall beautifies

Sunny pump

Sunny pump from American performs well and provides great power for the whole hydraulic system.

Germany EMB Tube

Germany EMB Tube and Connectors, reduce the odds against welding slag jamming the valves or affect oil flowing

Sealing Ring from NOK, Japan

Improve the service life of oil cylinder Guarantee long-term use without leakage

SIEMENS Main Motor

To guarantee press brake service life, and reduce the noise when working

High precision grating feet

High precision grating feet installed on the C-type rack, overcome the fuselage bending deformation folded in half the influence of accuracy.

Safety Fence

Protective guards on each side can protect the user during operation

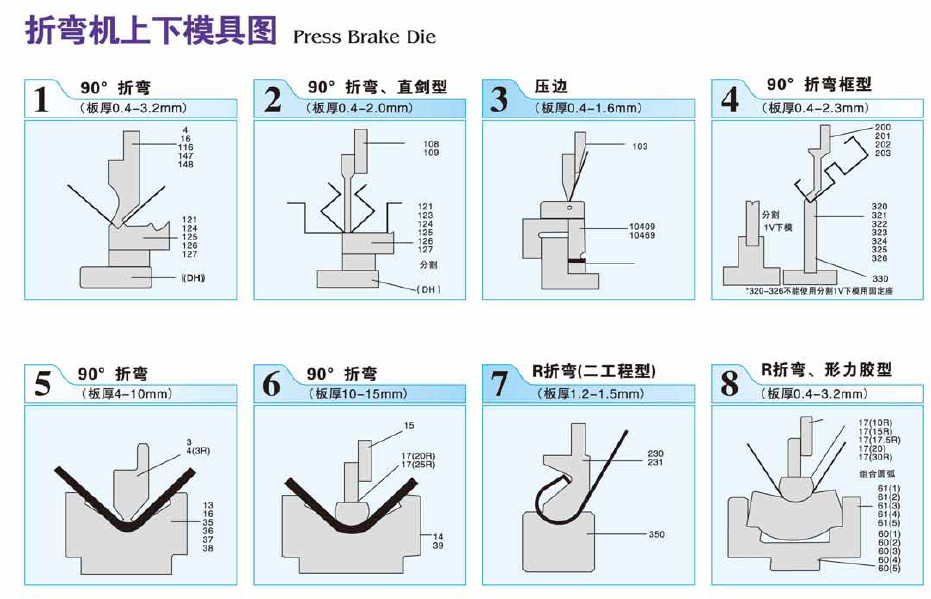

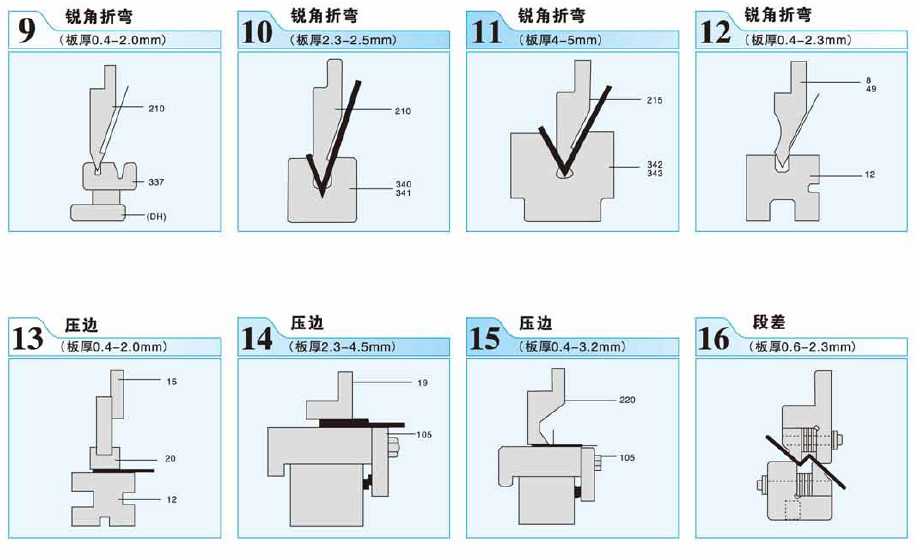

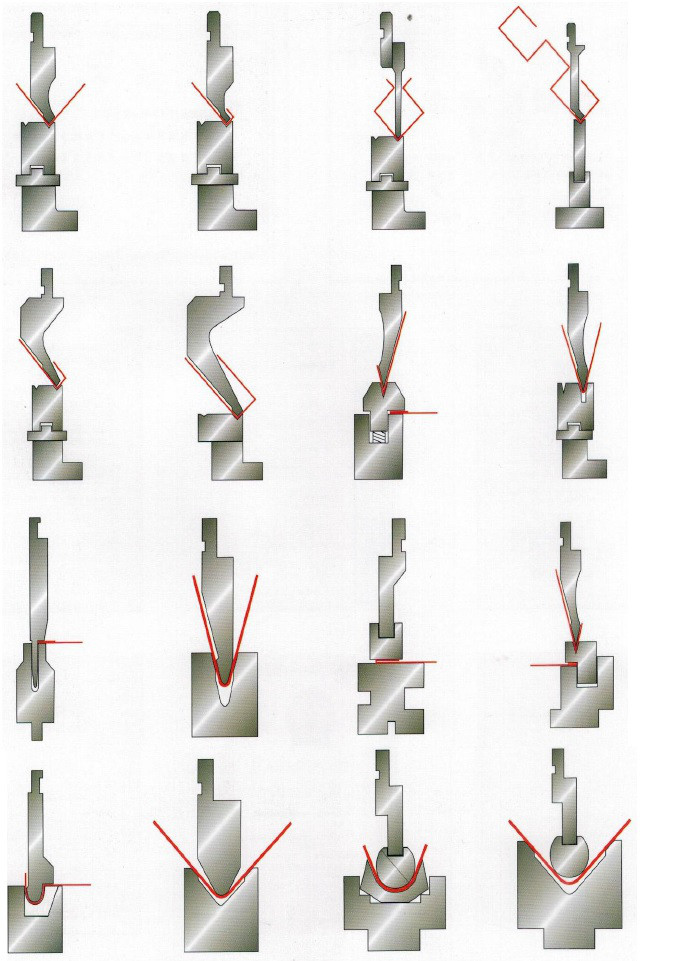

Press brake mold

All machines and molds (die/punch) can be customized according to requirements

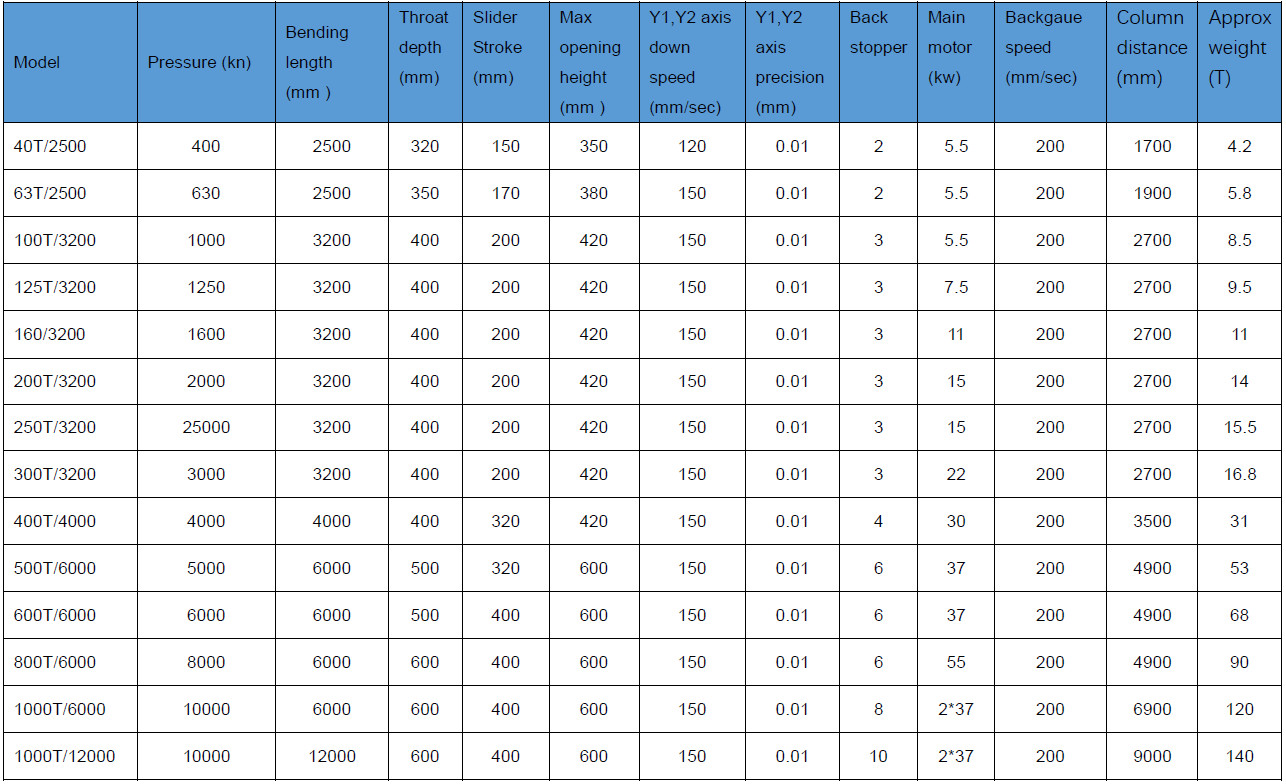

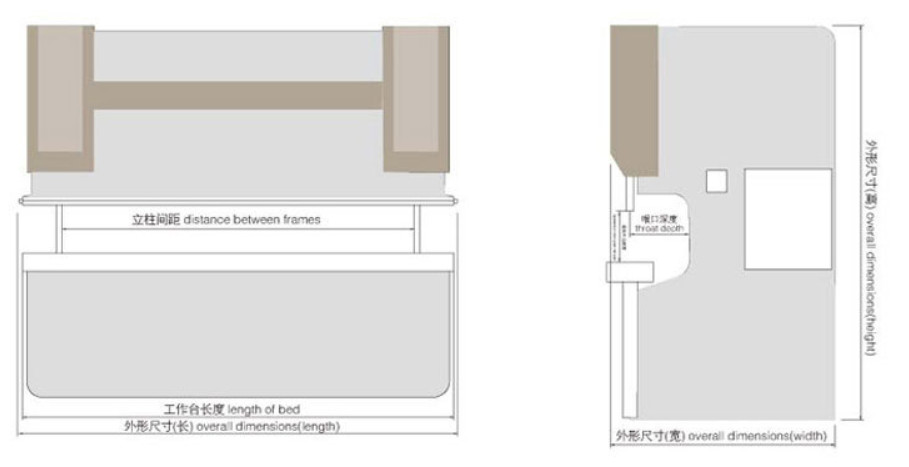

Technical

Optional