The laser is an important part of the fiber laser cutting machine. Therefore, in winter maintaining the laser storage temperature is also very important for using the machine. The user needs to know the information below.

- What is the storage temperature of the laser?

- Do you need antifreeze?

- How should the water-cooling pipeline and related components be protected?

In the severe winter, when the air temperature is lower than 0°C, the liquid water will condense to form a solid. In the process of solidification, the volume will become larger. This will "crack" the pipes and components in the water cooling system (cold water). The system includes a chiller, laser, and output head).

1. Do not turn off the water chiller at night

The water cooler is not turned off at night. At the same time, to save energy, the low and normal temperature water temperature is adjusted to 5 ~ 10 ℃ to ensure that the coolant is in a circulating state and the temperature is not lower than ice.

2. Use antifreeze as a coolant

When the use environment is often power cut and does not have the conditions to drain the coolant every day, antifreeze must be used. The basic liquid of antifreeze is generally composed of alcohol and water, which requires a high boiling point and flash point, high specific heat and conductivity, low low-temperature viscosity, not easy to foam, and does not corrode metal parts, rubber hoses, etc. When selecting or mixing antifreeze, its freezing point should be 5°C lower than the lowest temperature of the operating environment.

3. The choice of antifreeze

Add professional brand antifreeze to the water chiller, such as Clariant's AntifrogenN antifreeze, the addition ratio is 3:7 (3 is antifreeze, 7 is water). After adding the antifreeze, it can resist -20°C without freezing. If the temperature is below this range, please consult the water chiller supplier to confirm the proportion of antifreeze.

4. Precautions for using antifreeze

No antifreeze can completely replace deionized water and cannot be used for a long time throughout the year. After winter, the pipeline must be cleaned with deionized water or purified water, and deionized water or purified water must be used as the coolant.

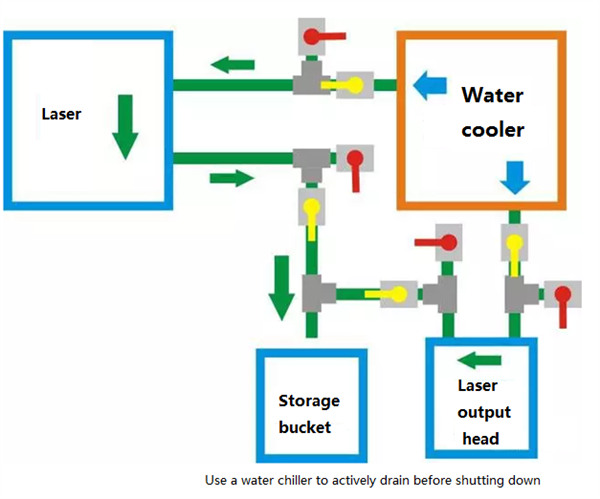

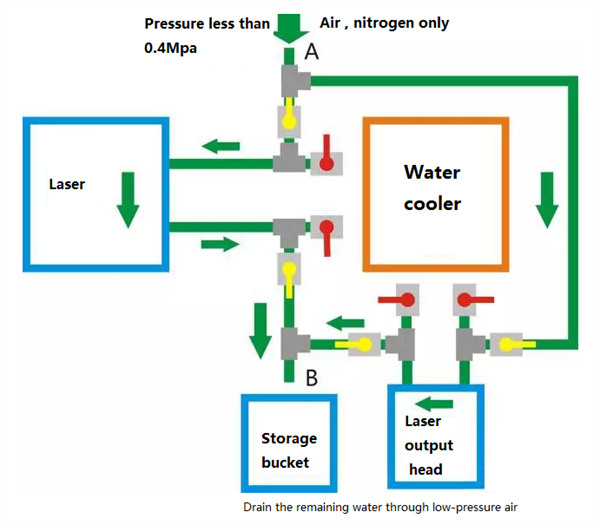

5. Program reference

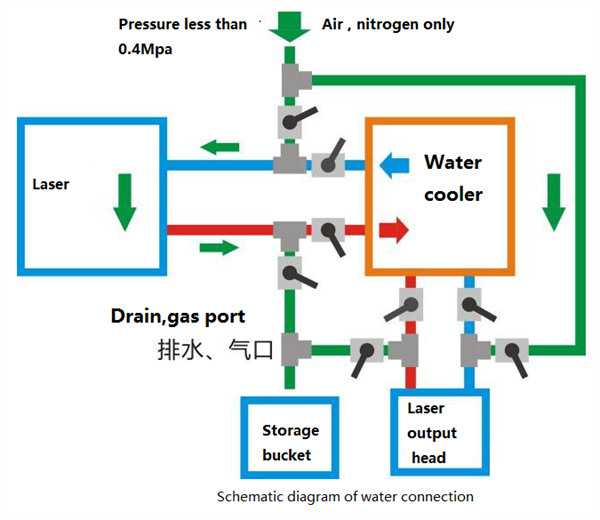

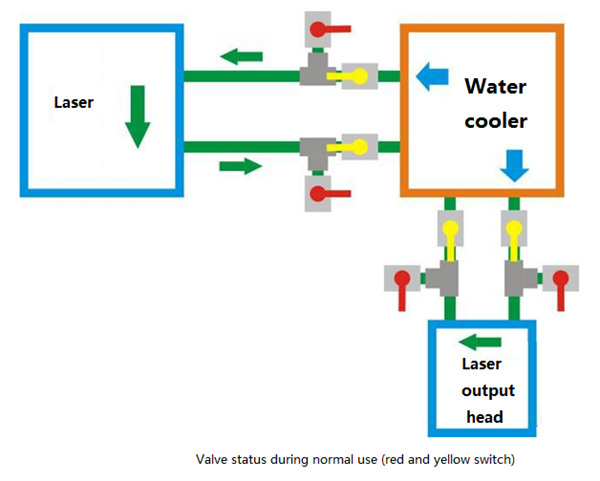

In the extreme cold weather in winter, all cooling water in the laser, laser output head, processing head, and water chiller must be cleaned to effectively protect the entire set of water cooling pipelines and related devices.

Close the red-marked valve and open the yellow-marked valve according to the requirements of the figure. And pass in clean compressed air or nitrogen not higher than 0.4Mpa (within 4 kg) to point A until no water droplets blow out from the outlet of point B.

Note that the water droplets on the pipe wall may form ice crystals and impact the optical fiber and crystal of the optical cable under the push of water flow. Please make sure to ventilate until there are no water droplets in the pipe.

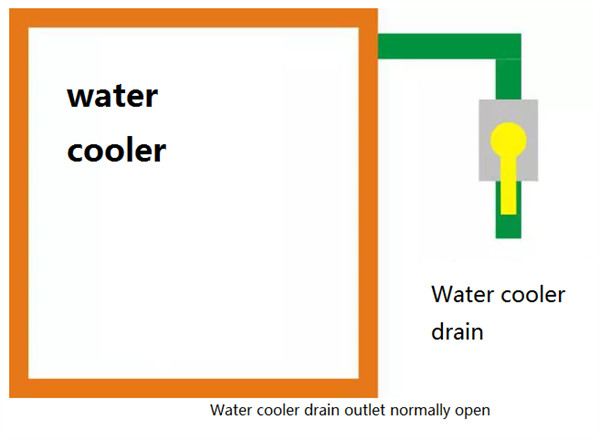

Finally, open the drain of the water cooler to empty the remaining water in the final water tank.

6. Reminder

Extremely cold weather can cause irreparable damage to the optical part of the laser. Please be sure to store and use the laser strictly in accordance with the storage temperature and working temperature specified in the China laser metal cutting machine manual. Pay attention to prevention and protection.

(When the Winter coming, it is time to add antifreeze. And the chiller should be kept 24 hours non-stop to avoid damaging the laser. For any question please contact at [email protected] )