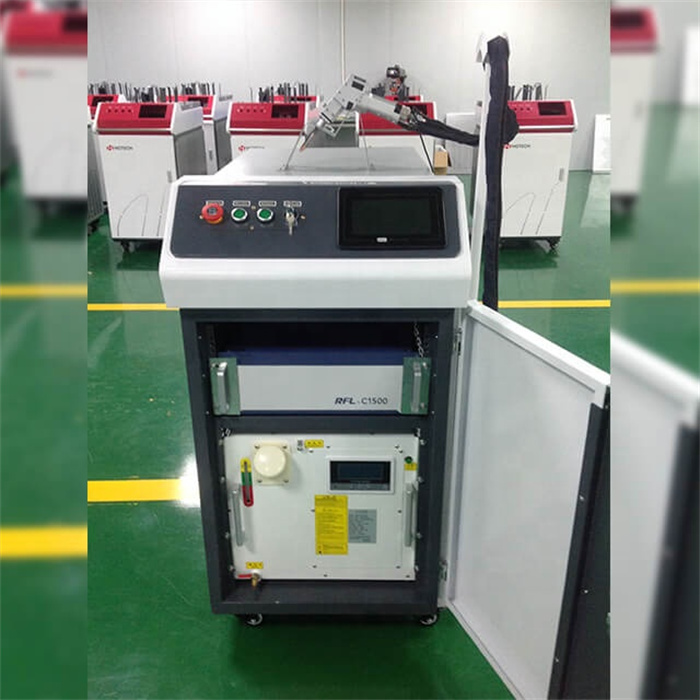

Product Description

1. Machinery in the laser equipment industry, fill the gap in manual welding

2. Simple operation, beautiful welding beam, welding speed, no consumables

3. Welding stainless steel sheet, iron sheet, galvanized sheet, iron sheet and other metal

materials, which can completely replace traditional argon arc welding, electric

welding and other processes

4. It can be widely used in cabinets, kitchens, stairs, elevators, frames, ovens, stainless steel, steel door and window railings, distribution boxes, stainless steel homes, complex irregular welding, etc.

Product Parameter

Brand | OPTIC |

product name | Handheld laser welding machine |

Laser power | 1000W 1500W 2000W |

Laser source | IPG / RAYCUS / JPT / MAX |

Welding head | Swing head/normal head |

cooling system | Water cooling |

Laser type | Fiber laser source |

Adjustable power | 5%—100% |

power supply | 220V/50/60HZ;380/50/60HZ |

Laser wavelength | 1064nm, 1064nm |

Dimensions | 1200x800x1480mm |

warranty period | 2 years |

weight | 280 KG |

Advantages of laser welding swing head

1.The process that the conventional head cannot complete, the jitter head only needs to use about 70% of the power, so the cost of the laser can be saved;

2.Through the galvanometer motor weaving back and forth, so that there are a lot of impurities in the bubbles can reduce bubbles,frying, splashing, etc.

3.In the case of irregular gaps, the requirements for fixtures can be reduced.

The welding gap of the conventional oscillatory joint is usually 0.2 mm, and the light directly exceeding this width passes through. The width of the welding gap of the swing head can reach 0.5mm, but the traditional welding head can only be welded to 0.2mm. There is no welding head of the galvanometer motor inside, so there is no swing.

The welding effect is not good, and the welding process is limited.

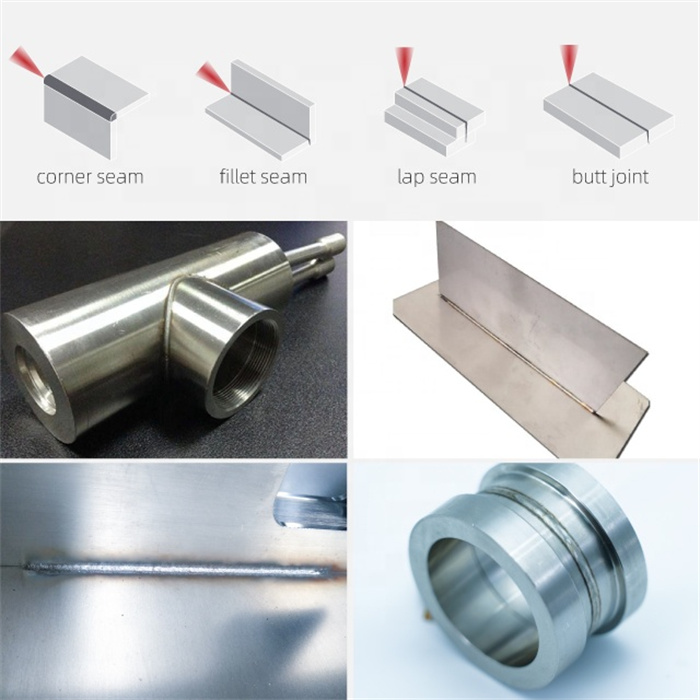

Welding Sample